Why Spare Parts Longevity Matters

Cone crushers often operate under heavy loads for long periods. Excessive wear of parts can lead to reduced output, higher energy consumption, and unexpected downtime. Extending the lifespan of wear parts is essential for lowering operational costs.

Common Causes of Wear

- Hard Materials: Basalt and iron ore cause strong abrasion on concaves and mantles.

- Uneven Feeding or High Moisture: Leads to localized stress and accelerated wear.

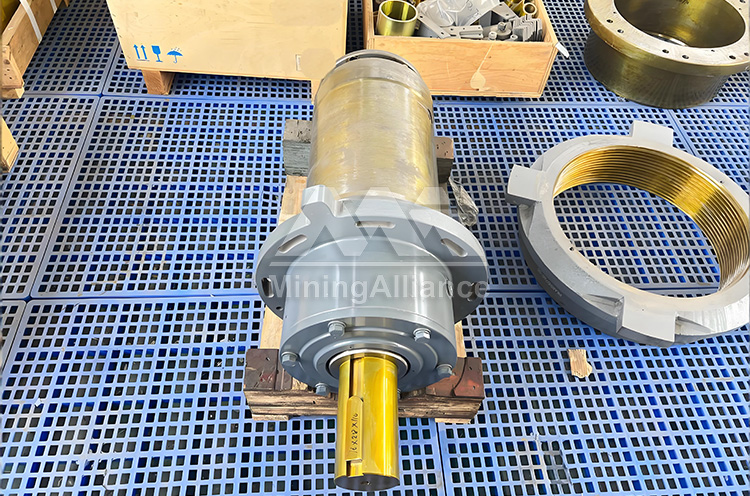

- Poor Lubrication: Causes friction and overheating between the eccentric and main shaft.

Three Strategies for Longer Lifespan

Ensure continuous and even feeding to prevent underload or overload conditions. OEM parts fit better and provide balanced hardness and toughness for longer service life. Check critical wear zones every 500 hours and replace damaged components promptly.

Role of Intelligent Monitoring

Modern cone crushers can be equipped with vibration, temperature, and oil pressure monitoring systems to detect wear or lubrication issues in real-time, automatically alerting maintenance teams to prevent failures.