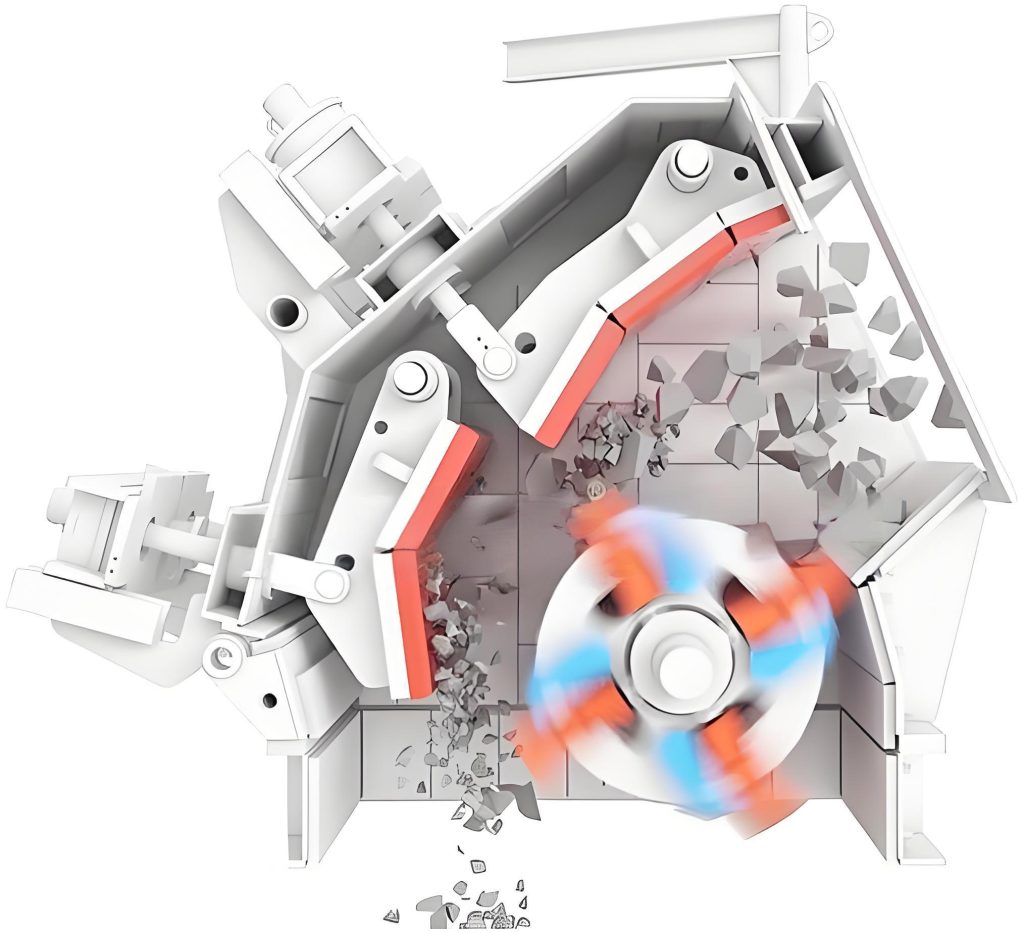

The blow bar is the core wear-resistant component of an impact crusher and is directly responsible for crushing materials. Installed on the rotor, the blow bar strikes incoming raw materials at high speed, generating strong impact force to achieve crushing. Its wear resistance, toughness, and structural design directly determine the performance and efficiency of the crusher.

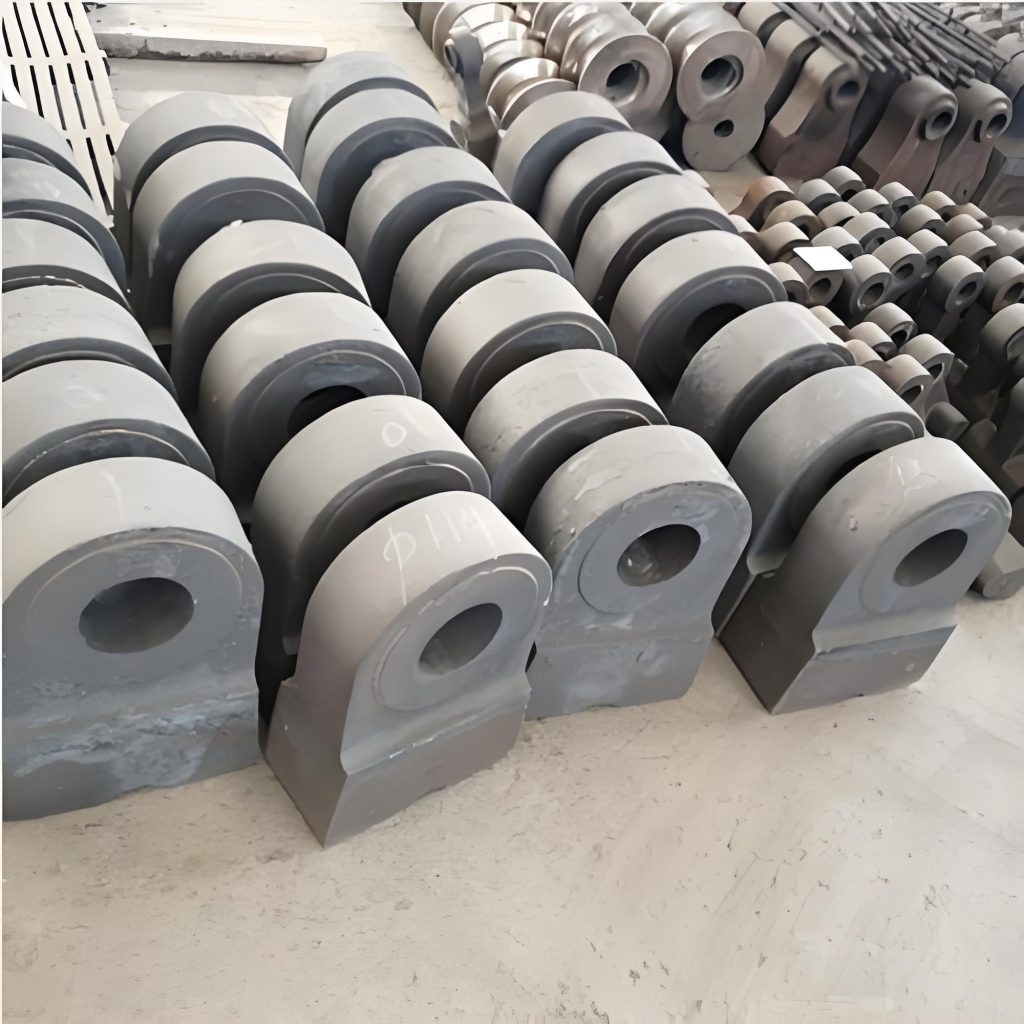

Commonly used blow bar materials include high manganese steel, high chromium cast iron, and composite wear-resistant materials. High manganese steel offers excellent toughness and impact resistance, while high chromium cast iron provides superior hardness and wear resistance. In some working conditions, composite blow bars combine the advantages of both, balancing durability and service life.

The quality of the blow bar directly affects the crusher’s output size, efficiency, and operating stability. A severely worn or damaged blow bar can result in uneven particle sizes, increased vibration, and even rotor damage. Therefore, timely maintenance and replacement of blow bars are essential for safe and efficient operation.

Furthermore, different types of blow bars are designed for specific applications. For example, harder materials such as granite or basalt may require high-chromium blow bars, while softer materials like limestone may be better suited for manganese steel blow bars. Selecting the proper blow bar type not only enhances crushing results but also significantly reduces operational costs.

In conclusion, the blow bar plays a decisive role in the overall operation of an impact crusher. By choosing high-quality blow bars and conducting timely maintenance, users can achieve higher crushing efficiency, longer service life, and better economic benefits.