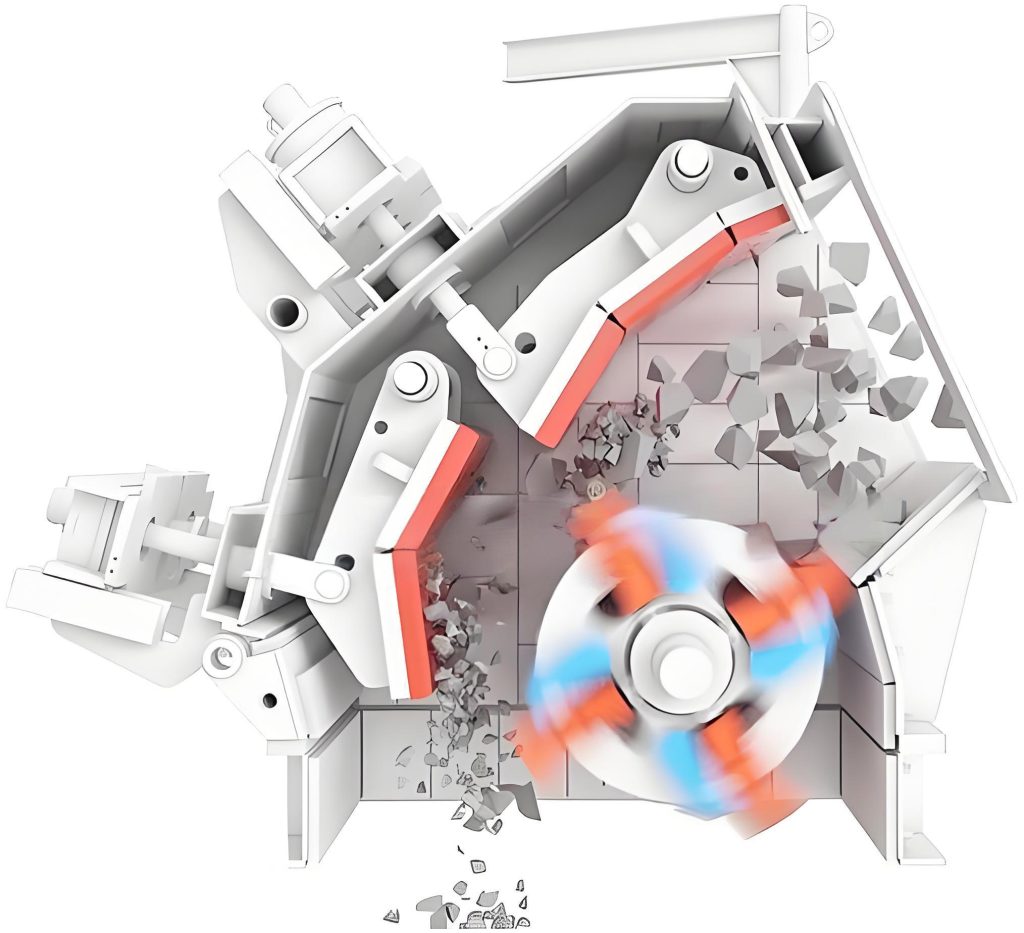

The side liner of an impact crusher is one of the key wear-resistant parts inside the crushing chamber. During operation, the raw materials collide with the rotor and impact plates at high speed, and the side liner serves as an auxiliary protective component. Its primary function is to protect the crusher frame from direct abrasion caused by materials and to ensure the overall stability and reliability of the equipment.

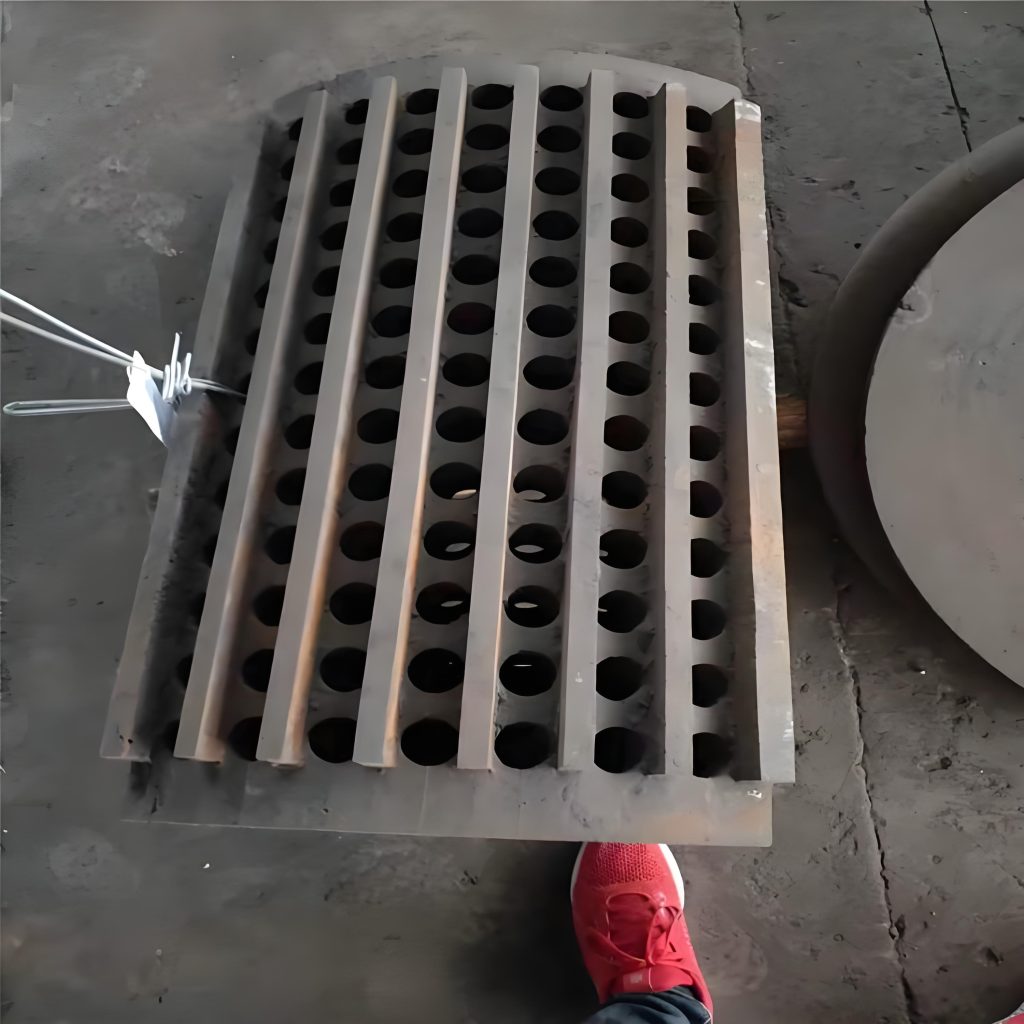

The side liner is usually made of high manganese steel, alloy steel, or other high-strength wear-resistant materials. These materials provide excellent hardness and toughness, allowing the liner to withstand continuous high-speed impacts and friction. By preventing direct contact between materials and the crusher housing, the side liner effectively prolongs the service life of the machine and reduces maintenance costs.

Regular inspection and timely replacement of the side liner are crucial for maintaining crushing efficiency. Once the liner is severely worn, it may reduce the crushing chamber’s integrity, leading to decreased productivity and possible damage to other parts. Therefore, users should monitor wear conditions and replace liners according to usage intensity.

In addition, high-quality side liners can also help optimize material flow inside the chamber, reduce energy consumption, and improve crushing performance. This makes them an essential part in ensuring that impact crushers operate stably and efficiently for long periods.