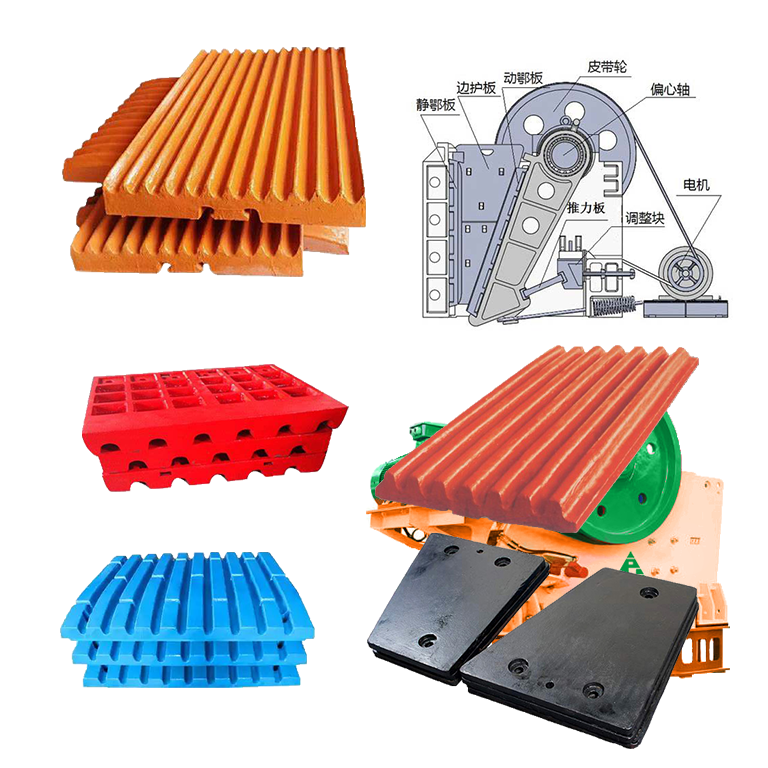

Jaw crushers play a critical role in primary crushing, handling large, abrasive rocks under intense impact and compression. Their wear parts—such as jaw plates, cheek plates, and toggle plates—must withstand extreme working conditions. As a result, the casting technology behind these components directly determines equipment reliability, service life, and operational efficiency. Among the various materials used, high manganese steel remains the industry standard due to its unique work-hardening ability and excellent toughness.

Why High Manganese Steel Dominates

Common grades include ZGMn13, ZGMn13Cr2, ZGMn18, and ZGMn22. These alloys are widely used because:

- Strong work-hardening capability

Their surface rapidly hardens under impact while maintaining a tough core. - Excellent toughness

Suitable for absorbing the continuous crushing forces in jaw crushers. - Superior wear resistance

Effective when processing medium and high-hardness stone.

By adjusting manganese, chromium, and alloying elements, casting engineers can fine-tune hardness, toughness, and overall durability.

The Foundation of Casting Quality

Jaw crusher parts are large, irregular castings, requiring well-designed molds. Critical considerations include:

- Shrinkage allowance

- Gating and riser system layout

- Hot spot distribution and cooling rate

- Wall thickness compensation

A properly engineered mold minimizes casting defects such as shrinkage cavities, cracks, and porosity, ensuring a dense internal structure.

Precision Determines PerformanceHigh manganese steel is typically melted at 1400–1500°C, with strict requirements:

- Stable melting temperature

- Low impurity content

- Uniform chemical composition

Pouring must be performed quickly and at high temperature to ensure full mold filling and prevent cold shuts or segregation.

The Key to Hardening Ability

After casting, components undergo solution treatment involving:

- Heating to 950–1100°C

- Holding for uniform austenitization

- Rapid water quenching

This process provides:

- A homogeneous austenitic structure

- Increased toughness and ductility

- Improved ability to work-harden during operation

This heat-treatment step is essential to achieving high durability in service.

Machining and Surface Reinforcement

Once heat-treated, jaw crusher parts undergo machining:

- Bolt holes and fitting surfaces

- Tolerance correction

- Surface finishing

Advanced manufacturers also incorporate technologies such as:

- Hard-facing welding

- Ceramic reinforcement coatings

- Composite surface layers

These further increase the service life of jaw plates and cheek plates.