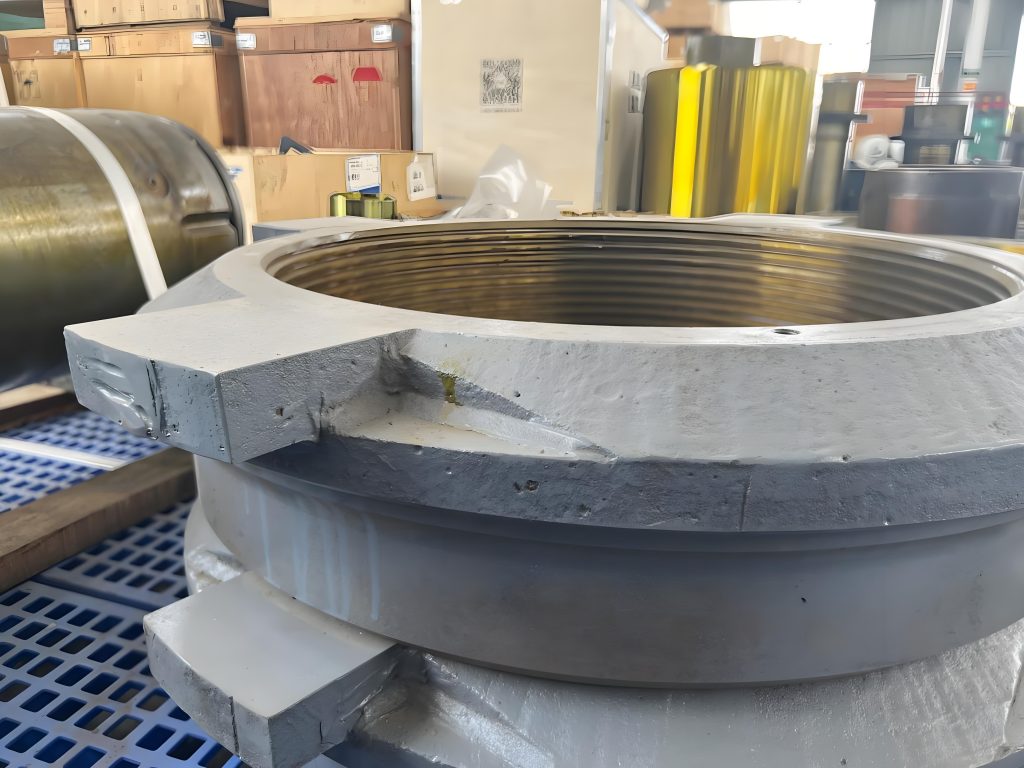

The outer nut is one of the essential components of a cone crusher. It is primarily used to secure the eccentric sleeve, maintain axial force, and protect critical components. It plays a vital role in ensuring the safe operation and high-efficiency performance of the cone crusher.

Main Functions:

- Secures the Eccentric Sleeve

The outer nut secures the eccentric sleeve through the locking mechanism, ensuring the stability of the crushing chamber. - Maintains Axial Force

During crushing operations, the outer nut helps maintain axial force balance, preventing uneven stress on the eccentric shaft and ensuring consistent crushing efficiency. - Protects Critical Components

The outer nut effectively protects the bearings, eccentric shaft, and other critical parts, extending the service life of the equipment. - Facilitates Maintenance

When used with a hydraulic system, the outer nut can be quickly assembled, disassembled, and adjusted, reducing downtime and improving maintenance efficiency.

Material and Advantages:

- High-Strength Steel: Ensures load-bearing capacity and compressive strength.

- Surface Heat Treatment: Enhances wear resistance and longevity.

- Precision Machining: Guarantees tight fit with other components, improving overall stability.

Application Scenarios:

The outer nut is widely used in cone crushers for mines, sand and gravel plants, construction waste recycling, and large-scale engineering projects. Whether in hard rock crushing, aggregate production, or concrete recycling, the outer nut ensures safe, stable, and efficient operation of the crushing line.

Choosing high-quality cone crusher outer nuts is essential for ensuring equipment performance, extending service life, and improving production efficiency. With proper installation and maintenance, the cone crusher can operate efficiently, creating greater economic value for enterprises.