Crushers are vital equipment in industries such as mining, construction, and metallurgy, performing crucial tasks in material processing. However, ensuring continuous and efficient operation of crushers depends on the proper selection and management of spare parts. The right crusher parts can increase equipment efficiency, extend its life, reduce maintenance costs, and ultimately improve production efficiency. This article will examine the importance of spare parts selection, strategies for optimizing spare parts management, and how to improve parts usage efficiency through smart technologies.

1. The Impact of Crusher Spare Parts on Production Efficiency

Crusher spare parts bear significant wear and tear during operation. The performance and quality of these parts directly affect the crusher's operational efficiency, product quality, and maintenance costs. Specifically, spare parts influence production efficiency in the following ways:

- Improved Crushing Efficiency: High-quality spare parts ensure that equipment operates smoothly under high loads, increasing crushing efficiency and reducing downtime. For instance, high-quality hammers and wear-resistant liners help reduce friction between the material and the equipment, improving the crushing process.

- Extended Equipment Life: Choosing the right material and design for parts reduces wear, thus extending the crusher’s service life. This minimizes downtime and the cost of repairs or part replacements, ensuring long-term, cost-effective operation.

- Reduced Production Costs: Premium spare parts reduce the need for frequent replacements and maintenance, lowering operational costs. Durable parts also improve production continuity and reduce the likelihood of breakdowns.

- Improved Product Quality: The correct selection and optimization of spare parts ensure that the crushed material meets the required size and quality standards, enhancing the competitiveness of the final product in the market.

2. Principles for Choosing Crusher Spare Parts

When selecting crusher spare parts, several factors must be taken into account to ensure that the parts maximize the crusher's production efficiency. Key principles to consider include:

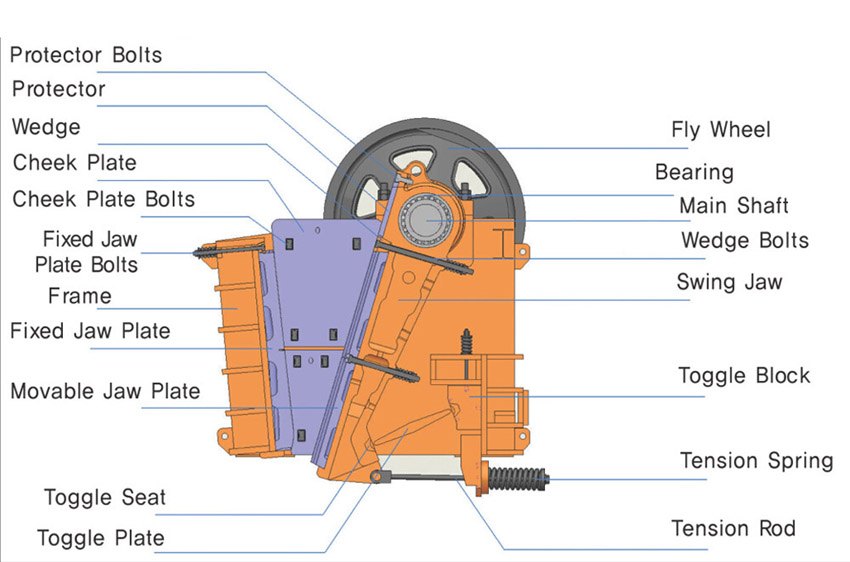

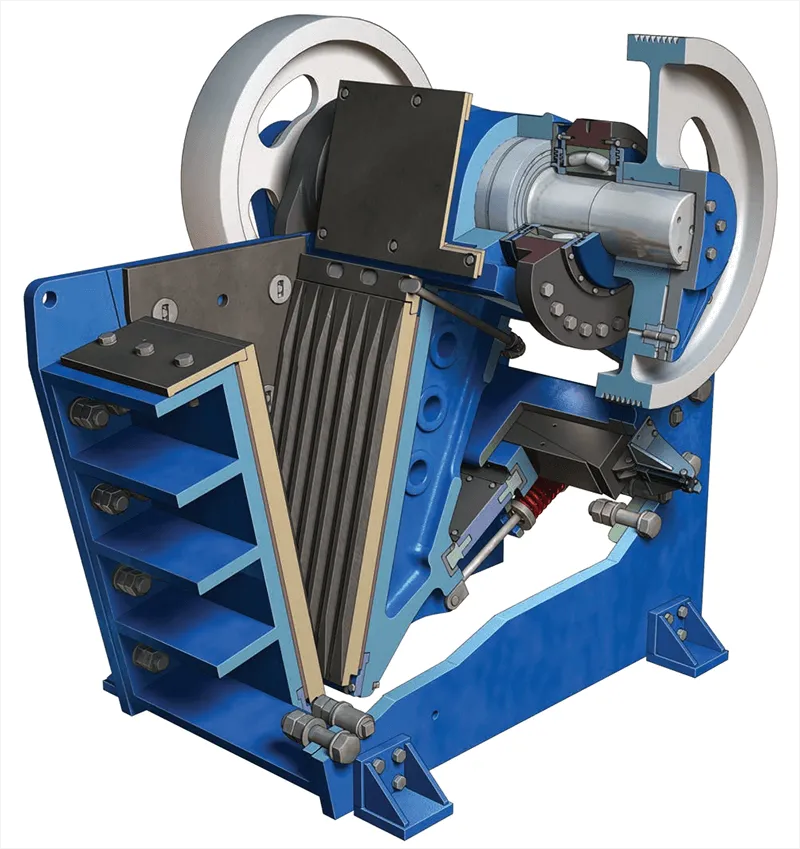

- Adaptability and Wear Resistance: The material choice for spare parts affects their wear resistance and durability. For high-wear components like hammers, jaw plates, and impact plates, materials such as high manganese steel and alloy steel are commonly chosen due to their superior resistance to wear.

- Manufacturing Precision and Compatibility: The precision of manufacturing impacts the part’s performance. High-precision parts ensure a tight fit with other crusher components, reducing operational instability and potential damage.

- Environmental Compatibility: Different production environments require different characteristics in spare parts. For instance, parts exposed to high temperatures or corrosive substances need to be resistant to heat and corrosion to survive in harsh conditions.

- Cost-Effectiveness: While part cost is an important consideration, it should not be the sole deciding factor. A comprehensive evaluation of the part’s durability, performance, and maintenance costs will lead to the best cost-benefit ratio.

3. Optimizing Spare Parts Management

In addition to choosing high-quality parts, effective management and maintenance of these parts are essential to ensure the efficient operation of crushers. Optimizing spare parts management can greatly improve equipment efficiency and reduce operating costs. Some common strategies for spare parts management optimization include:

- Implementing Spare Parts Inventory Management Systems: Efficient inventory management ensures timely replacement of worn-out parts, avoiding production delays due to stockouts. By using inventory management software, businesses can track parts in real-time, proactively scheduling procurement and replacements.

- Regular Maintenance and Inspections: Regularly checking and maintaining parts helps identify wear early and allows for timely replacements. By keeping detailed records of spare parts usage, businesses can optimize replacement cycles and minimize unplanned downtime.

- Using Smart Monitoring Systems: With IoT and AI technologies, businesses can implement smart monitoring systems to track the operational status of crushers and spare parts. Real-time monitoring of parameters like vibration, temperature, and pressure allows businesses to detect abnormal wear early and schedule predictive maintenance to avoid failures.

- Providing Technical Support and Training: Offering technical support and training for operators helps them choose, install, and maintain parts effectively, reducing the risk of equipment damage caused by improper handling.