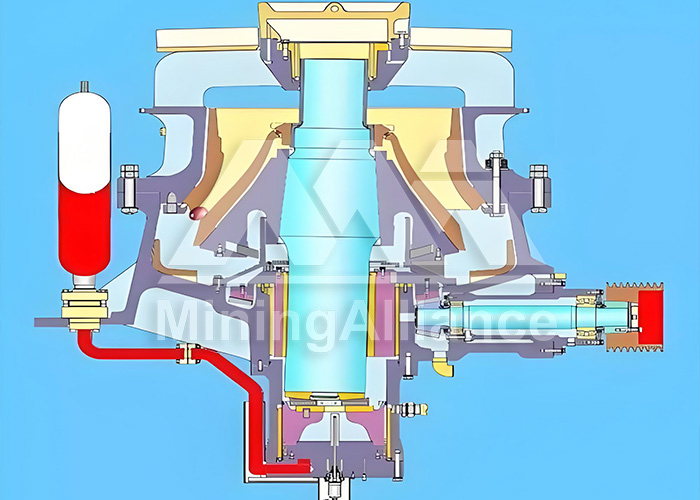

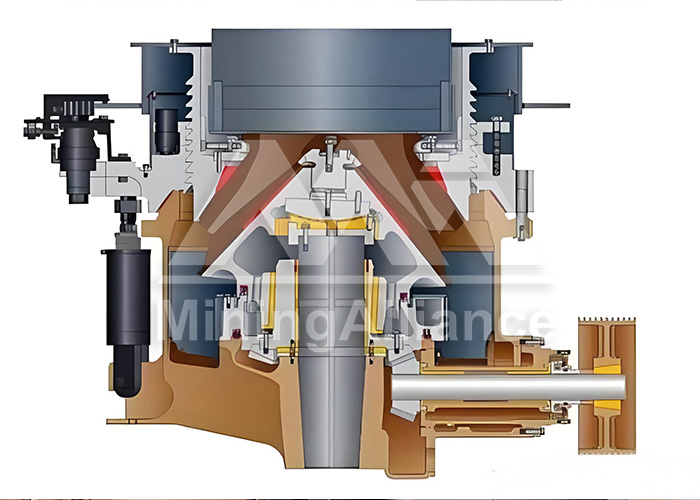

The lubrication system minimizes friction, reduces wear, and extends the life of bearings and transmission parts.

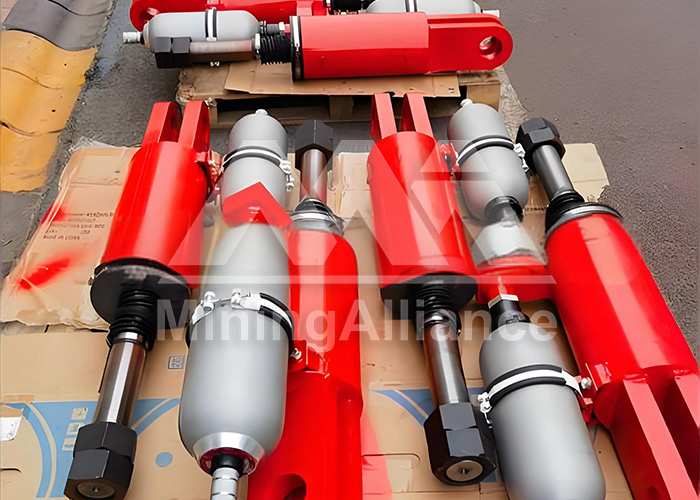

Modern crushing equipment is equipped with centralized lubrication systems that automatically deliver oil to critical bearings and joints. Our systems use high-viscosity, oxidation-resistant lubricants and feature smart modules to monitor temperature and pressure in real time.

Scheduled lubrication greatly reduces mechanical failures and eliminates risks associated with manual greasing. Remote monitoring and alarm functions are available, making it ideal for jaw crushers, cone crushers, screens, and conveyors.

A well-maintained lubrication system enhances machine reliability and ensures stable, continuous production.