In a jaw crusher, the jaw plate—also known as the tooth plate—is the primary component that directly contacts and crushes the material. Its performance affects not only the crusher’s efficiency but also its service life and operating costs. This article provides a detailed look into the structure, material selection, wear patterns, and maintenance of jaw plates, helping users optimize performance and usage.

1. Structure and Classification of Jaw Plates

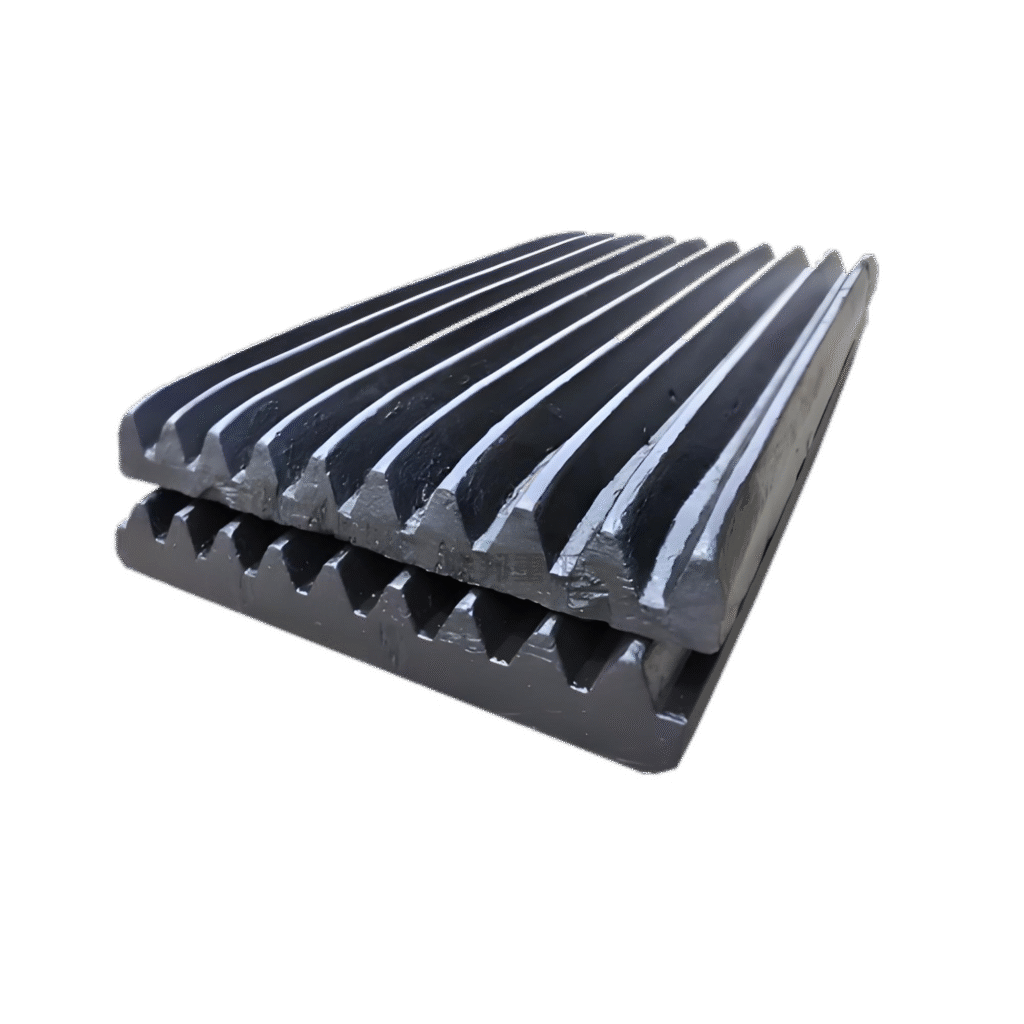

A jaw crusher typically includes two jaw plates: the movable jaw plate and the fixed jaw plate. The movable jaw reciprocates, forming a compressive zone with the fixed jaw to crush incoming material. Jaw plates are often designed with toothed surfaces to increase grip and crushing force.

Based on mounting position and operational demand, jaw plates can be further classified into upper/lower plates, corrugated plates, or straight-tooth plates—each suited for different working conditions.

2. Common Materials and Properties

Jaw plates are usually made from high manganese steel (Mn13, Mn18, Mn22), medium alloy steel, or composite materials. High manganese steel is the most commonly used due to its excellent work-hardening properties—it becomes harder as it absorbs impact and pressure.

For crushing high-hardness materials such as granite or iron ore, high manganese-chromium alloys or titanium-molybdenum enhanced composites are recommended for superior strength and crack resistance.

3. Wear Mechanisms and Failure Modes

During operation, jaw plates experience repeated impact, compression, and shearing, leading to common issues such as uneven wear, grooving, cracking, and corner breakage. When processing hard rock or under continuous operation, deep grooves can form, reducing throughput and product quality.

Typical causes of premature failure include oversized feed, foreign metallic objects, worn eccentric shafts, loose mounting bolts, and poor lubrication.

4. Usage Recommendations and Maintenance Tips

- Material and Profile Selection: Choose jaw plates based on material type and crusher model. Deep-chamber designs suit large feed; fine-tooth profiles are ideal for secondary crushing.

- Reversible Use: Jaw plates can often be flipped to use the unworn side, extending service life.

- Tightness Check: Inspect jaw plate bolts regularly to avoid loosening caused by vibration.

- Feed Control: Avoid feeding oversized material or metallic debris to prevent impact damage.

- Wear Monitoring: Keep a wear log to forecast replacement schedules and implement planned maintenance.

5. Conclusion

As the most critical wear part of a jaw crusher, the jaw plate’s quality and management strategy determine the equipment’s reliability and operating cost. With proper material selection, standard use, and timely maintenance, users can significantly improve efficiency, reduce spare parts consumption, and maximize the productivity of the entire production line.