In industries such as mining, construction, and metallurgy, crushers play a pivotal role in processing various minerals, building waste, and other materials. To ensure the long-term and efficient operation of crushers, the selection and maintenance of spare parts are crucial. This article explores the types of crusher spare parts, factors to consider when choosing them, and the market trends in crusher parts.

1. Types of Crusher Spare Parts

Crusher spare parts refer to components that endure significant pressure and wear during the equipment’s regular operation. These parts directly impact the crusher’s efficiency, production capacity, and service life. Common crusher spare parts include:

- Crusher Hammers (or Impact Plates): These are core components used to strike and crush material. Depending on the type of crusher, hammers may be made of high manganese steel, alloy steel, etc.

- Screens and Screen Plates: Used in the screening system to classify the crushed material according to the required size. These are typically made from abrasion-resistant steel or high-strength alloys to increase durability.

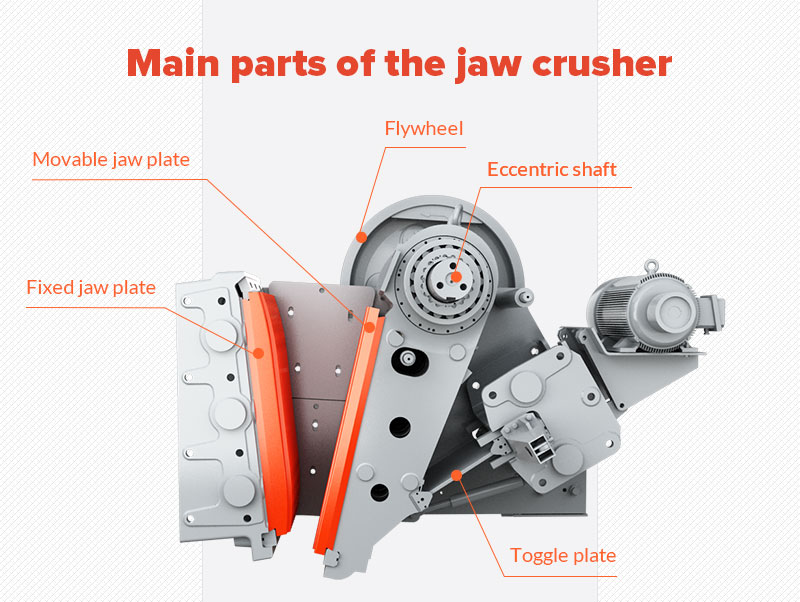

- Jaw Plates and Impact Plates: Jaw plates are used in jaw crushers, while impact plates are employed in impact crushers. Both parts are in direct contact with the material, so they need to be highly durable and resistant to wear.

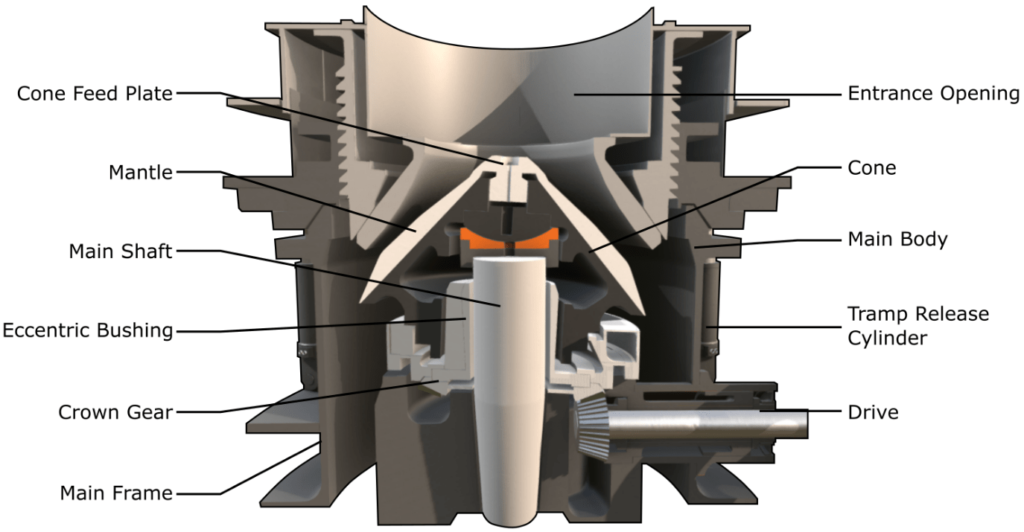

- Rotors and Shafts: The rotor is a crucial part of the crusher that feeds the material into the crushing chamber, providing the necessary force. The shaft is the central rotating element, bearing significant load, and the choice of material directly impacts the crusher's performance and service life.

- Liners and Stators: Liners protect the interior of the crusher, minimizing friction and wear, while the stator houses the rotor.

2. Key Factors in Choosing Crusher Spare Parts

Choosing the right crusher spare parts is essential to enhance the equipment’s efficiency, extend its service life, reduce maintenance costs, and ultimately improve production benefits. The following are key factors to consider when selecting crusher spare parts:

- Material Selection: The material of the spare parts determines their wear resistance, impact strength, and overall durability. High manganese steel, alloy steel, and chromium-alloy steel are commonly used for high-wear parts due to their superior wear resistance.

- Manufacturing Precision: The manufacturing precision of spare parts plays a critical role in their performance. Parts that are manufactured to high tolerances ensure tight fits with other crusher components, reducing instability and potential damage.

- Adaptability to Working Environment: Different working conditions require different features in spare parts. For instance, in high-temperature or corrosive environments, selecting parts with high temperature resistance and corrosion resistance is crucial.

- Cost-Effectiveness: While the price of spare parts is a consideration, it should not be the sole factor. The durability of the parts, along with their overall performance and maintenance costs, should be considered to achieve the best cost-benefit ratio.

3. Optimizing Spare Parts Management

In addition to selecting high-quality spare parts, managing and maintaining these parts effectively is essential for ensuring the efficient operation of crushers. Optimizing spare parts management can significantly enhance equipment efficiency and reduce operating costs. The following are common strategies for spare parts management optimization:

- Establish Spare Parts Inventory Management Systems: Efficient inventory management ensures timely replacement of worn-out parts, avoiding production delays due to stockouts. Using inventory management software can help track spare parts in real-time, enabling proactive procurement and replacement scheduling.

- Regular Maintenance and Inspection: Regularly checking and maintaining crusher spare parts helps detect wear early and allows for timely adjustments or replacements. By maintaining detailed records of spare part usage, businesses can optimize replacement cycles and minimize unplanned downtime.

- Use of Smart Monitoring Systems: With the advancement of IoT and AI technologies, many companies now use smart monitoring systems to track the operational status of crushers and their spare parts. By monitoring parameters such as vibration, temperature, and pressure, abnormal wear can be detected early, and predictive maintenance can be implemented to avoid failures.

- Technical Support and Training: Providing technical support and training for operators ensures they can choose, install, and maintain spare parts more effectively, reducing the risk of damage due to improper handling.

4. Market Trends and Future Development

With technological advances and changes in industry demand, the crusher spare parts market is evolving. The following are some key trends:

- The Development of High-Performance Materials: To improve the wear resistance and service life of spare parts, manufacturers are increasingly adopting new high-performance materials, such as ceramic composite materials and ultra-high-strength alloy steels, which can withstand higher loads and harsher working conditions.

- The Rise of Intelligent Spare Parts Management Systems: With the development of smart manufacturing and IoT, intelligent spare parts management systems are becoming more widespread. By using data analytics and predictive maintenance, businesses can more accurately monitor spare part conditions and reduce downtime and repair costs.

- Customization and Personalized Demand: As customer needs become more diverse, the demand for customized spare parts is growing. Businesses are offering tailor-made solutions to meet the specific working environments and production requirements of different clients, improving overall efficiency.