Characteristics of Wear Parts in Sand Making Machines

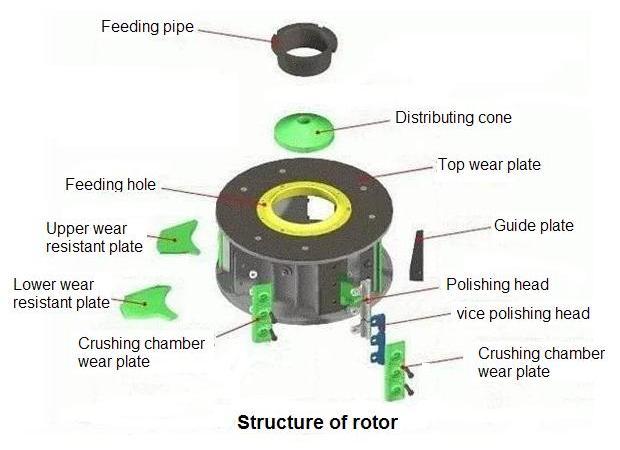

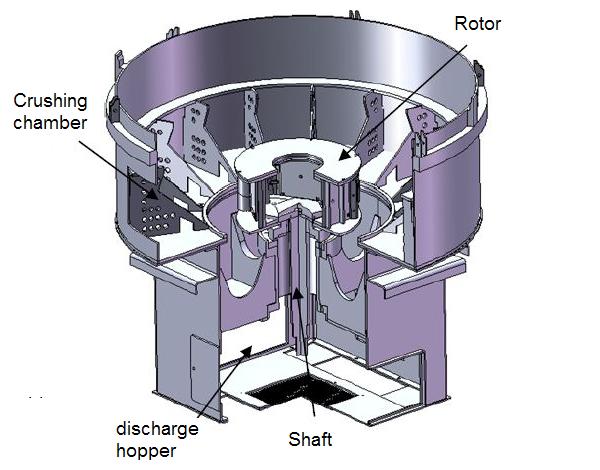

The high-load operation of sand making machines results in gradual wear of core components such as throwing heads, peripheral guard plates, and impact blocks. The wear level of these parts directly affects production efficiency, finished sand quality, and energy consumption. Regular inspection and timely replacement of wear parts are crucial for the stable operation of the machine.

Common Wear Parts and Recommended Replacement Cycles

- Throwing Head: Check every 300-500 hours and replace if worn or cracked.

- Peripheral Guard Plate: Inspect every 1000 hours; replace when severely worn.

- Impact Block: Replace every 500-800 hours to maintain optimal crushing performance.

- Main Shaft & Bearings: Regular lubrication and monitoring prevent overheating and abnormal vibrations.

Maintenance Strategies

- Routine Inspections: Implement regular inspections to detect wear and prevent major failures.

- Material Selection: Use high-durability alloy parts for extended lifespan.

- Operational Optimization: Control feeding amount and size to prevent overloading.

- Lubrication Maintenance: Regular oiling minimizes friction and enhances efficiency.

Conclusion

Proper maintenance significantly reduces wear part replacement frequency, enhances production efficiency, and maximizes economic benefits.