Importance of Sand Making Machine Accessories

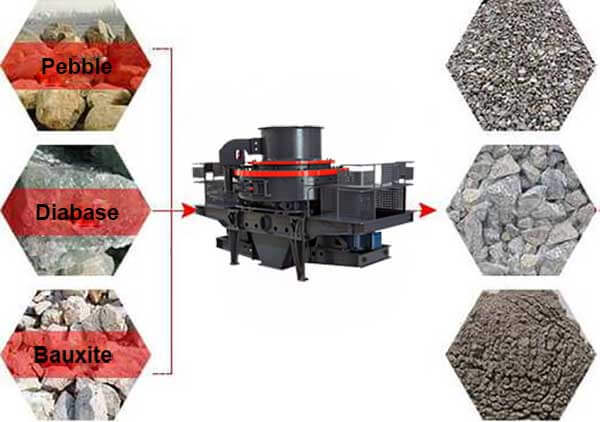

The sand making machine is the core equipment in a sand production line, and its efficient operation depends on the coordinated performance of various key accessories. These components not only affect the machine’s lifespan and efficiency but also directly impact the quality of the finished sand and overall production costs. Proper selection and maintenance of sand making machine accessories can significantly enhance the stability of the production line, minimize downtime, and improve economic benefits.

Common Sand Making Machine Accessories and Their Functions

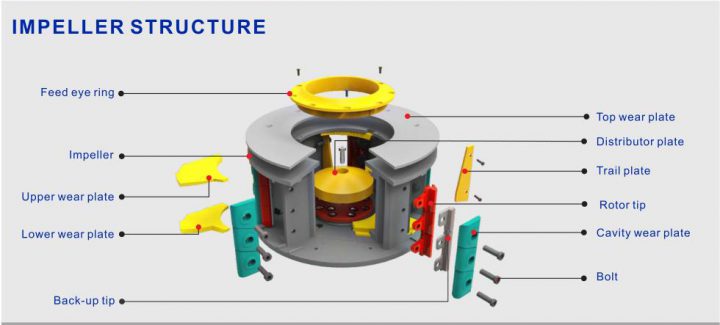

- Throwing Head: One of the core components responsible for accelerating and propelling materials into the crushing chamber. It is usually made of high-chromium alloy or tungsten carbide to improve impact resistance and durability.

- Peripheral Guard Plate: Protects the internal structure of the machine from direct material impact. A high-quality guard plate can effectively reduce equipment wear and optimize the crushing process for better efficiency.

- Impact Block: Plays a crucial role in the material crushing process, determining the crushing effect and particle shape. A wear-resistant impact block reduces energy consumption and enhances crushing efficiency.

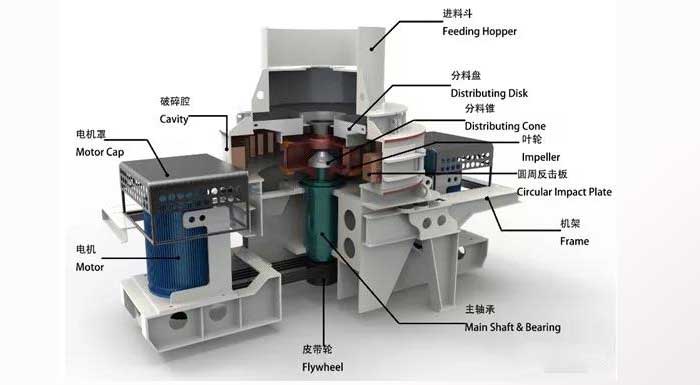

- Bearings and Lubrication System: High-quality bearings ensure smooth long-term operation, while an optimized lubrication system reduces friction and extends the equipment's lifespan.

- Rotor Assembly: The core power component of the sand making machine, directly affecting crushing efficiency. A high-precision rotor assembly ensures machine balance at high speeds, reducing vibration and improving operational stability.

How to Choose High-Quality Sand Making Machine Accessories

- Wear Resistance: Select components made from high-durability materials such as high-chromium alloy and alloy steel to extend lifespan.

- Precision and Compatibility: Ensure that the accessories are fully compatible with the machine model to improve installation accuracy and operational stability.

- Brand and Quality Assurance: Preferably purchase from reputable brands or authorized suppliers to guarantee product quality and after-sales service.

- Ease of Maintenance: Some accessories adopt modular designs, making them easier to replace and maintain, thus reducing machine downtime.

Conclusion

The selection and maintenance of sand making machine accessories are crucial factors in improving production efficiency and reducing operational costs. Choosing high-quality, wear-resistant accessories and performing regular maintenance can effectively extend the machine’s service life and enhance the overall efficiency of the sand production line.